High Airflow Carbon Adsorbers

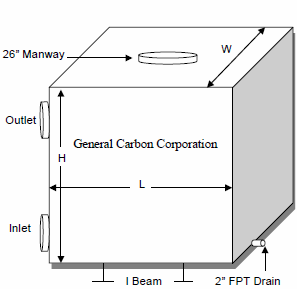

General Carbon’s Vapor Box series of carbon adsorbers are versatile high airflow units. Each filter is easily transportable via the “l” beams support structure or lifting lugs. The large bed surface area in each model allows for the treatment of higher airflow rates. The Vapor Box adsorbers are constructed of mild steel and have two part epoxy coatings on the inside and industrial enamel on the outside to provide long service life. They are equipped with a manhole large enough for easy carbon changeouts. Several different grades of virgin and reactivated carbon are available to satisfy any of your filtration requirements.

| Name | L x W x H | CFM | Carbon WT. | IN/OUT | Bed Volume FT^3 | PSIG | Max Vacuum |

| VB 1000 | 4 x 4 x 5’3” | 15 – 720 | 1000 | 6 inch | 36 | 2 | 6 |

| VB 2000 | 4 x 4 x 6’5” | 15 – 720 | 2000 | 6 inch | 72 | 2 | 4 |

| VB 3000 | 4 x 6 x 7’7” | 240 – 1500 | 3000 | 8 inch | 108 | 1 | 2 |

| VB 5000 | 6 x 8 x 7’10” | 480 – 3000 | 5000 | 10 inch | 180 | 1 | 1 |

| VB 10000 | 8 x 10 x 9 | 800 – 5000 | 10000 | 12 inch | 360 | 1 | NR |

| VB 20000 | 8 x 20 x 9’4” | 1600 – 10000 | 20000 | 18 inch | 720 | 1 | NR |

| VB 40000 | 8 x 40 x 9’4” | 3200 – 20000 | 40000 | 18 inch | 1440 | 1 | NR |

*Vapor Boxes are also available in stainless steel.

Installation and Startup – The Vapor Box adsorbers require no special procedure for startup. Remove the shipping covers from the inlet and outlet and make the proper connections to your system. The unit is now ready for service and can be started up. Unions or quick-disconnect fittings are recommended if the unit will be disconnected frequently. Multiple units are usually connected in series with testing advised between the units to determine when the first unit needs to be changed-out.

Maintenance – When in use, the Vapor Box requires no maintenance other than the monitoring of the influent and effluent air streams and the operating pressure of the system. Monitoring the air stream into the last unit in a series arrangement is a recommended safeguard against breakthrough in the final outflow. When the concentration of contaminants in the outflow equals the concentration in the inflow, the Vapor Box has reached its removal capacity and should be removed from service. The working life of each adsorber is dependent upon the type of contaminant in the air stream as well as its concentration and the air flow rate. A pressure relief device is advised to prevent damage to the canister in the event of excessive pressure buildup.

Recharging – Once the carbon is saturated by contaminants, the unit should be removed and replaced with a fresh one. To purchase replacement carbon or to arrange for a carbon change-out, please contact our office.

Disposal – Dispose of the spent carbon in accordance with Local, State and Federal regulations.

CAUTION!

Wet activated carbon removes oxygen from air causing a severe hazard to workers inside the carbon vessels. Confined space/low oxygen procedures should be put in place before any entry is made. Such procedures should comply with all applicable Local, State and Federal guidelines.

FIRE! When vapor phase activated carbon adsorbs chemicals, a heat of adsorption is given off. The treated air flow is the only way this heat is removed from the bed. If the chemical concentration is high and the gas flow is small, the heat created in the carbon bed can accumulate to the point where a bed fire is started. In addition, if you are dealing with flammable chemicals, understand the correct operation of your system. If you have any questions about the fire potential of your system, please call General Carbon Corporation at 973-523-2223.